Manufacturing Operations

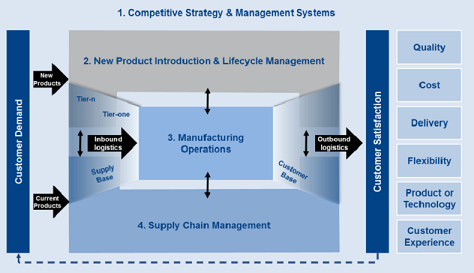

The key to the success of any manufacturing company is its ability to efficiently utilise people, processes, materials and equipment to add value to products or services that its customers then purchase.

Businesses must define clearly what is the value-added product or service that is important to their customer and then enable their manufacturing processes to efficiently and consistently deliver these.

Monitoring and controlling the key dimensions of quality, cost, delivery, flexibility, product innovation and customer experience will enable manufacturing teams to achieve and sustain high levels of global competitiveness.

In an ever changing global market place manufacturing companies that have flexible and efficient processes that consistently satisfy its customers demand are ideally placed to benefit from opportunities through new products, technologies or markets.

Aspen Global have a highly experienced team who will work at all levels in a company to design, implement and sustain flexible production systems with the ability to continually eliminate waste and adapt to changes in customer demand.

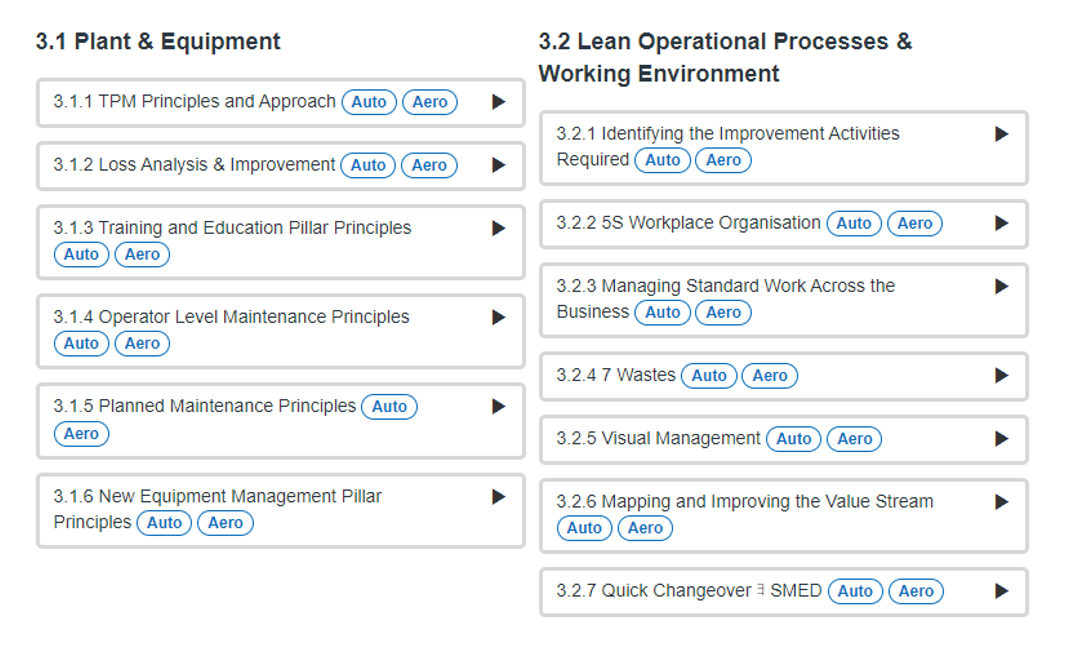

Our team is highly experienced in implementing lean operational processes and developing the working environment and team skills required to support this approach.

In highly automated environments where operational efficiency is key our team is experienced in enabling your whole operational team to take ownership of the performance of their plant and equipment through a highly structured TPM (Total Productive Maintenance) programme.